Automotive Projects

The Future Of Manufacturing: Automotive Automation

The future of manufacturing: Automotive Automation

Technology in the field of automotive automation is constantly improving. Automakers have grown to rely on high outputs and little downtime due to the introduction of additional technology such as 3D printed parts and the incorporation of accurate robotic line workers, which an all-human workforce simply cannot match.

In many ways, the automobile industry has served as a testbed for automation, as it was among the first to embrace the technology and continue to drive demand for it. In fact, the car industry alone accounts for roughly half of all industrial robots sales in North America. Not only has its adoption increased output and reduced downtime, but it has also resulted in a large increase in profitability for vehicle manufacturers.

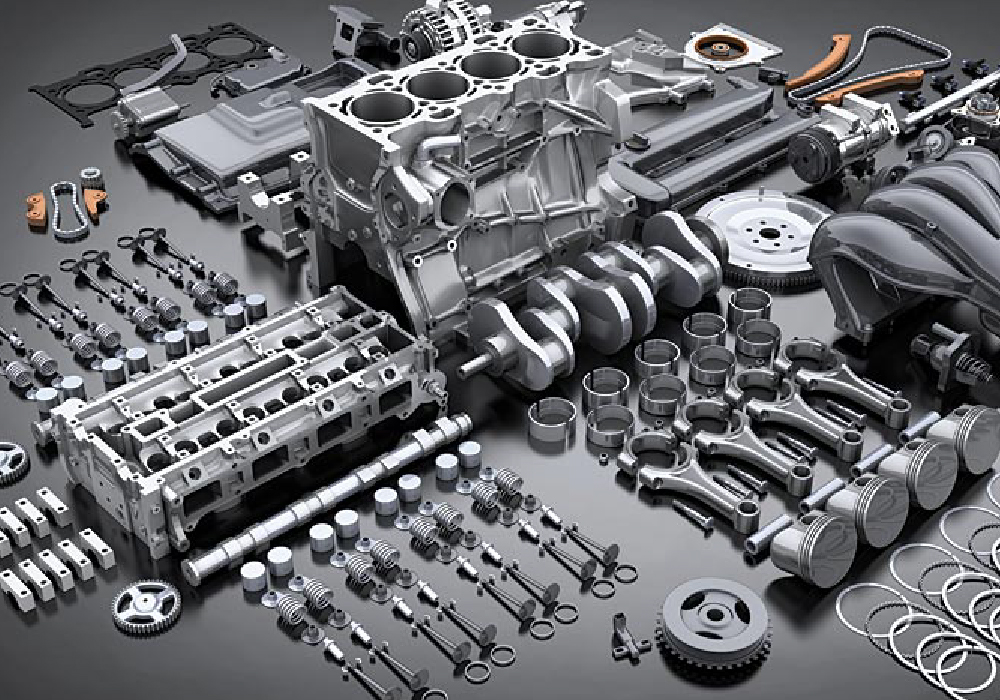

Engine Assembly Automation control System:

An automation system is a set of sensors, controllers, and actuators that work together to complete a task with little or no human input. Mechatronics is an interdisciplinary discipline of engineering that blends mechanical, electrical, and electronic systems, and it is the focus of this article.

The majority of automation systems are originated from manual procedures like drilling, cutting, and welding. Robotic arms are used in these systems to control the movement of the tool that performs the original job. Automation is used in other areas, especially in the field of process control, to monitor and control process parameters.

Automation Control System (ACS) is a control theory application utilised in various control systems for operating equipment such as machinery and processes in factories to regulate activities without direct human intervention. With initiating, stopping, monitoring, adjusting, and other functions, an ACS maintain and improves the functionality of a controlled object. The ACS function saves time and materials while also improving quality, accuracy, and precision.

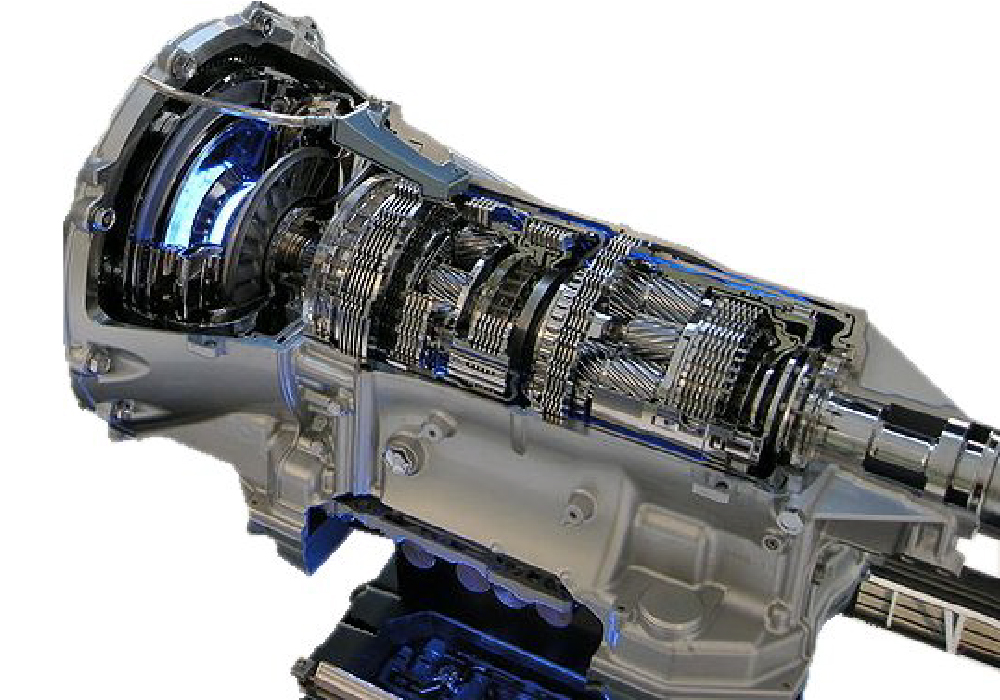

Engine transmission assembly control system

Simply put, a transmission assembly is a fancy way of expressing transmission. And your car’s transmission is one of the most important components. The transmission assembly is in charge of two main functions. First, it transfers the engine’s power to the driving wheels. In other terms, the gearbox is the intermediary that permits the car’s power to be converted into motion. Second, the transmission controls the engine’s output to ensure that sufficient power is available throughout the driving range.

The engine can only produce the appropriate amount of power at particular speeds, which is where the transmission comes into play. Gears of various sizes are used in most gearboxes. This permits the transmission to change the torque multiplier and output speed, allowing the engine to run more smoothly and effectively.

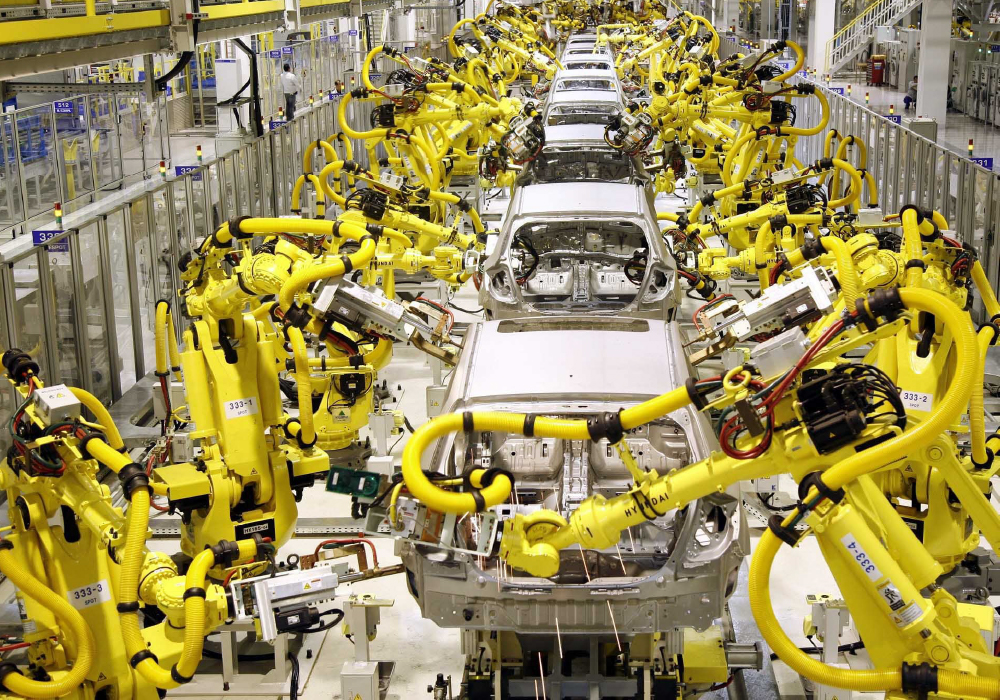

Vehicle Assembly line automation control system

An automated assembly line is made up of a sequence of workstations connected by a transfer system and an electrical control system. Each station performs a certain operation, and the output is processed sequentially as it goes through a pre-defined processing series along the line. Component families are managed by many of the automatic assembly lines we design for our clients. Satt Automation can design and adapt tools and equipment to meet and even surpass the client’s stipulated cycle time. Our engineers, manufacturers, and integrators have the expertise to properly integrate assembly automation into your manufacturing process.

Today’s business environment necessitates that you keep a close eye on all of your activities equipment, product flow, employee behaviour, data and that you cover all of your bases. You’re usually expected to do this with fewer resources than ever before. Assembly automation integrates everything and allows you to have more control over every detail.

Body shop line automation control system

The reduction of carbon footprint is one of the most difficult tasks facing the automotive industry. This means that not only do machines and processes need to save energy and run efficiently, but the finished product must also be environmentally beneficial.

Less polluting vehicles are gaining popularity, and they are no longer only a vision of the future but are becoming more prevalent every day. Minimize the vehicle’s body weight without compromising its toughness to handle crashes and cargoes is one of the most effective strategies to reduce fuel consumption.

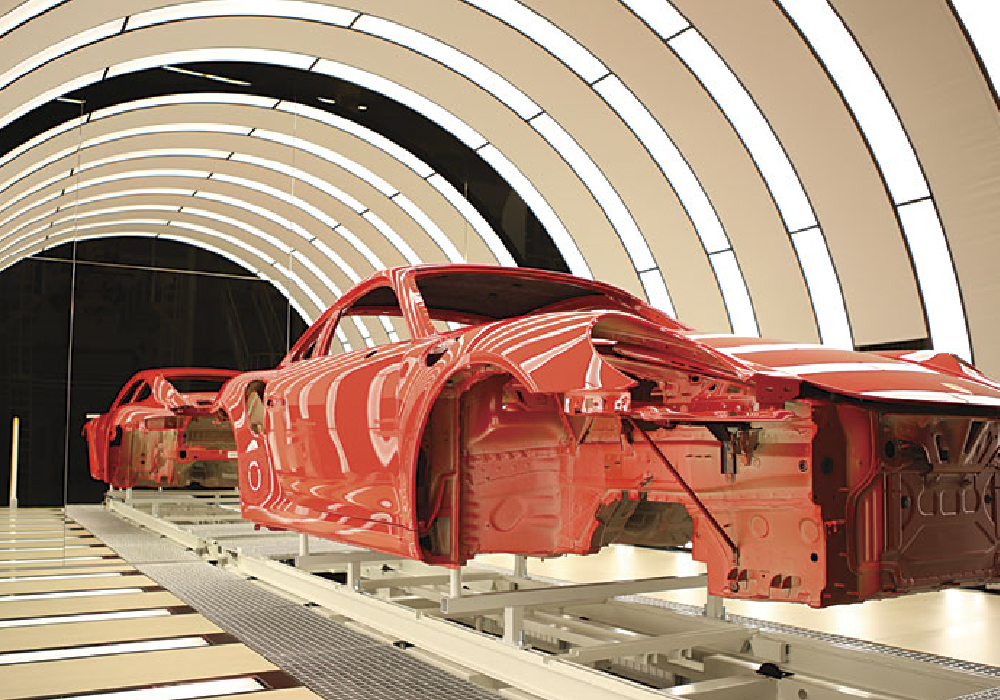

Paint shop automation work

The paint shop is where the vehicle’s look is determined. This is where you’ll get the colour and shine you need. Individual surface treatments perform crucial functional duties, such as corrosion prevention, soundproofing, and vibration damping, in addition to attractive elements.

A high-gloss finish that can be applied quickly and with minimal waste. This is the paint shop’s challenge. When it comes to painting volume, mixing ratio (air to paint), and motion, ultrahigh precision and perfect metering of the product are necessary during the painting process (carefully executed motion sequences)

Press shop automation work

Individual metal sheets that will subsequently be joined to construct the car body are made in press shops. Metal sheets are delivered in enormous rolls known as coils. The cut metal blanks are then placed in press lines and pushed into the desired shape using several press stages, allowing for the creation of extremely complicated geometries. From coil handling through hot shaping and final end-of-line approval, Satt automation equipment can be found throughout the press shop.

Satt Automotive products are utilised in this sector to transport workpieces between individual steps in the process swiftly and reliably. Suction cups are commonly utilised on end-of-arm tooling to allow for safe, precise handling even on very greasy surfaces and at high acceleration rates.

Foundry shop automation work

A foundry is a manufacturing facility that produces castings by melting metal, pouring liquid metal into a mould, and then letting it solidify. Even if you’ve never visited a foundry or even know what one looks like, the metal castings they manufacture are all around you. There’s a strong possibility you’re less than 10 feet away from one as you read this.

Foundries don’t merely make metal components for engines, railroads, or pipes. They also serve as components in machines that produce many of the basic consumer goods we rely on. Metal castings are used in 90% of all produced goods.