Conveyor Automation

An Integral Part Of Your Material Handling Needs

Conveyor systems are a typical piece of equipment in nearly every business. They assist in the completion of various duties, and by automating them, you can have the added benefits of flexibility and safe procedures. They also aid in the improvement of the efficiency and cost-effectiveness of your procedures.

Since the early twentieth century, conveyors have been utilised to transport various types and amounts of commodities. Conveyor systems are the backbone of material handling facilities, which include the transportation, storage, and control of commodities through various manufacturing and distribution operations. Other material handling devices, like forklifts, require continual back and forth movement from the start to the endpoint, disrupting the steady flow of compounds. Conveyors, on the other hand, allow for uninterrupted material transfer.

Roller conveyor

We offer a diverse range of industrial conveyors. It is used to transport objects from one location to another. As a result, the offered conveyor can allow for the smooth transfer of big things, saving humans time and energy. Heavy and bulky gadgets can be conveniently transported using an industrial conveyor. It is appropriate for usage in mining, manufacturing, warehouses, and other industries. It is naturally rust and corrosion-resistant. The offered range is generally employed in material handling applications, such as barrels, pallets, and other heavy industry items.

Belt conveyor

A belt conveyor is a type of conveying machine that continually transports things from one location to another. Conveyor frames, conveyor belts, conveyor pulleys, conveyor rollers, tension devices, driving units, and other components make up a belt conveyor machine. Stone, sand, coal, concrete, cement, gravel, fertiliser, mineral ore, limestone, coke, sawdust, wood chip, bulk material, grain, corn flakes, carbon black, and other commodities can be transported using a belt conveyor system.

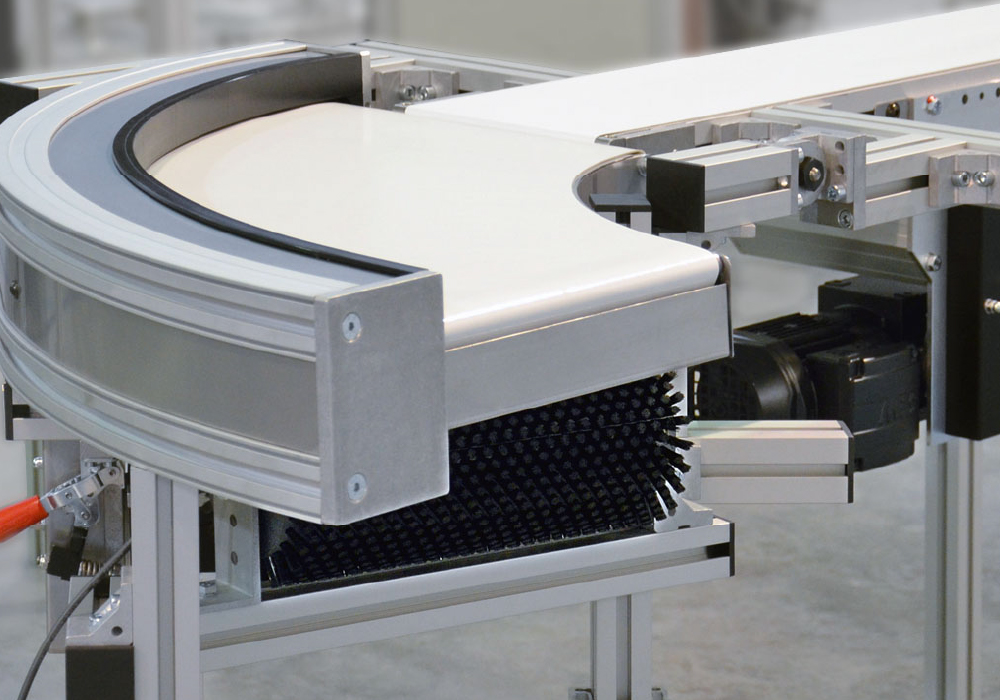

Slat / curved conveyor

Slat conveyors are a sort of conveying equipment that moves products from one end to the other using a chain-driven loop of slats. A motor drives the chain, which causes it to cycle like a belt conveyor. The key distinction is that this conveyor type uses slats connected to a chain, similar to car treads, instead of a rubber belt. As a result, every item on the conveyor has a hard, flat surface, which is perfect for a variety of products that cannot be used on rollers or belts due to their irregular shape. Slat conveyors may operate in hazardous, high-weight, and high-temperature conditions since the slats are often composed of engineering plastic or metal. Another significant benefit is that the slats may be made in a variety of shapes, providing them more applications than other conveyors. They are available in a variety of speeds and widths, with optional side railings to help guide goods through the conveyor system.

The slat conveyor is ideal for large materials that would otherwise destroy most conveyors, as well as for items that are hot or dangerous. They are commonly employed in manufacturing plants as assembly line conveyors and control the orientation of an object.

Chain conveyor

Chain conveyors can be customised to fit your process needs. They’re designed to keep your startup costs low and your running and maintenance expenditures low.

Drag chain conveyors and submerged chain conveyors are two different types of chain conveyors offered by Satt Automation. Both types of chain conveyors are commonly used to move coal, wood, garbage, and scrubber sludge in pulp and paper mills, waste to energy facilities, and coal-fired electric power plants.

Gravity conveyor

Gravity conveyors are one of the most cost-effective materials handling options. Loads are transported using rollers or skate wheels mounted in frames. Gravity conveyors are often slanted in elevation to allow products to flow freely while taking advantage of gravity. As a result, the label – gravity conveyor was created.

Boxes, cartons, and totes with hard, stiff bottoms can be moved using gravity conveyors. The size of the roller or skate wheels, as well as their spacing, will vary. A good rule of thumb is to always have at least three rollers under the box, carton, or tote.

Gravity roller conveyors are a cost-effective and versatile mode of transport with a wide range of applications. Conveyors of this type are the most widespread in the world.

Overhead conveyor

Our expert engineers deliver unique, custom design solutions to every work. We are an overhead conveyor firm that offers a comprehensive selection of high quality, durable overhead chain conveyor systems. Satt Automation has successfully maintained its ISO 9001 certification and has established a reputation as a pioneer in overhead crane production, design engineering, installation, and service of overhead conveyors. Satt Automation’s dedication to innovation, cost-effectiveness and customer service has helped it become one of the most reputable conveyor manufacturers in the world.

Pallet Conveyors

For industrial plants, warehouses, and distribution centres, pallet handling conveyors are not a one-size-fits-all solution. Satt Automation incorporates top-of-the-line technology that is tailored to your project’s specific needs in order to get things up and running quickly. Our pallet handling equipment has a proven track record of increasing throughput and flexibility while cutting total costs.

Pallet conveyors deliver discrete products on containers known as pallets through belts, roller chains, flat-top chains, or powered rollers for exceptionally high weights.

Pallet sizes are mostly specified in metric dimensions (e.g., 240 x 240 mm), while some manufacturers sell pallets in inch or non-standard metric measurements.