Plc Control Panels

&process Automation

Plc Automation Panels

Automatic parking systems (APS) are parking structures that stack cars vertically to save space. The designs of these one-of-a-kind systems allow vehicles to be transported from the entry to their parking area without the driver is there.

Satt automation’s automated parking systems employ modern robotic technology to park and retrieve vehicles within a secure garage. The exterior doors are activated by an automated identification system that allows drivers access to the garage. The driver then enters the transfer area, exits the vehicle, and the automated system moves the vehicle to a secure parking place once it is securely out of the transfer area.

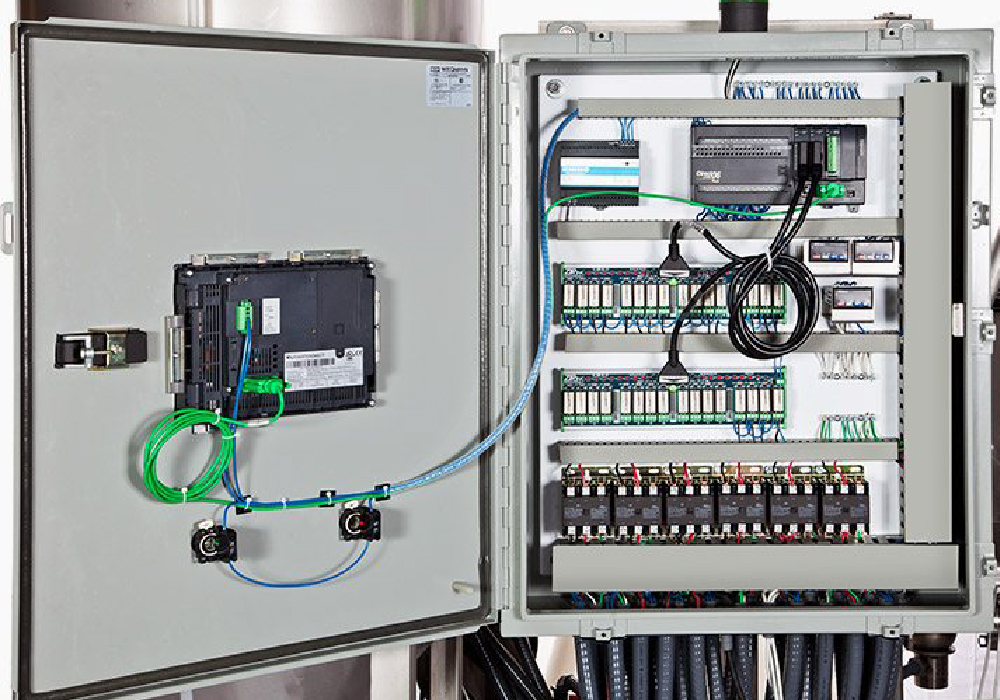

PLC control panel

A PLC can be set up to control just about anything. They’re suitable for airports, medical campus central utilities facilities, and manufacturing plants because of their performance, reliability, and scalability. PLCs also offer a high level of sophistication and redundancy for mission-critical applications, as well as the ability to tolerate harsh conditions thanks to industrial hardening.

Our engineers at Affinity Energy are experts in the design, programming, field installation, commissioning, and support of PLC control panels. We can programme PLCs using ladder logic, function blocks, and structured text, and we have experience with a variety of manufacturers.

Transfer schemes, energy curtailment, load shed, active power management, motor controls, and application-specific controls for motors, circuit breakers, transformers, inverters, generators, and battery systems are among our electrical application expertise.

Simulator control panel

The simulators were developed by modifying existing aviation and marine simulator principles for use in a diving context. The system is intended to give trainee supervisors with a realistic learning environment, as well as the ability to replicate events that may arise in the real world without putting a diver in the water.

Commercial divers have traditionally been at greater risk because the cost and practical limitations of delivering actual operational diving scenarios in an accessible, safe, and controlled training environment have severely hampered the quality of supervisor training.

VFD control panel

The VFD Panel (Variable Frequency Drive Panel), sometimes referred to as the VFD Control Panel, is used to regulate the speed of the electric motor and feed pump. Drilling, pumping, and other major machine applications such as Conveyor and Compressor make extensive use of them.

The voltage or frequency of an AC motor can be regulated in one of two ways. Due to the consistent flux density, frequency control provides greater control than voltage control. This is when the operation of VFDs becomes important. It is a power conversion device that converts the input power from a fixed voltage, fixed frequency to a variable voltage, variable frequency output for control.

Most industrial applications necessitate variable speeds during peak loads and steady speeds during normal operation. VFDs that operate in a closed loop maintain the motor’s speed at a consistent level, even when input and load disturbances occur.

Marking Machine System

Industrial direct component marking is becoming increasingly popular and important. Most products now have traceability and part identification built in from the beginning. Part marking requirements are dictated by government rules and industry standards bodies in almost every industry on the planet.

The marking machines and solutions offered by Satt Automation address the great majority of direct component marking applications required by industrial and manufacturing businesses.

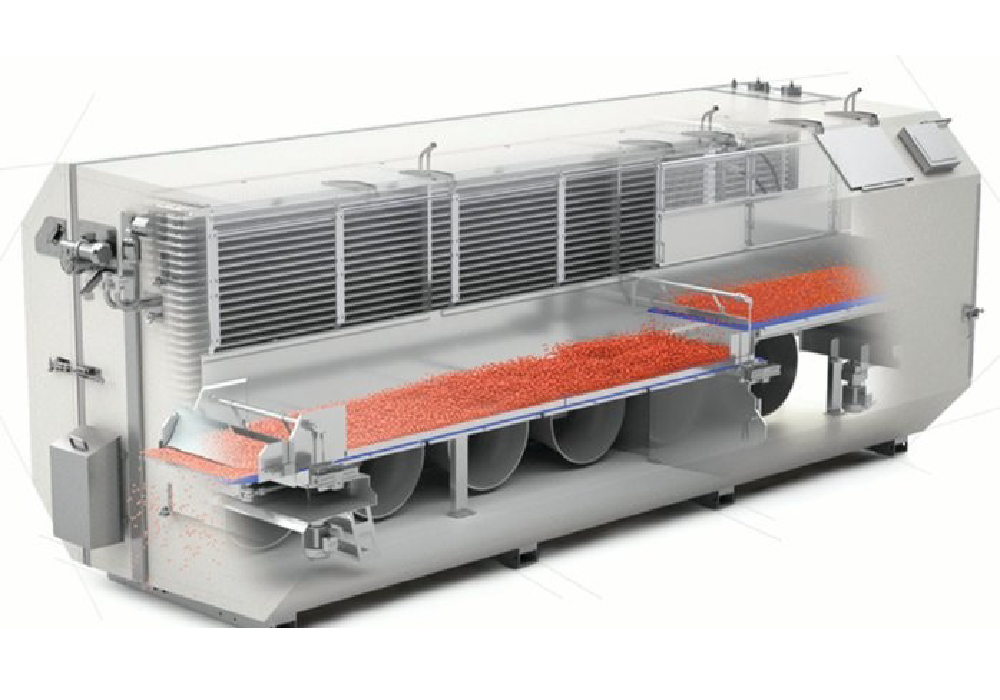

IQF freezer- 40-50 automation control system

Due to a number of significant features, the Satt Automation IQF freezer is well-known for constructing complicated and distinctive aerodynamics. The unique bedplate layout, overall freezer design and shape, and high-performance fans with frequency converters are all factors that contribute to a high-quality IQF outcome.

The airflow may be changed for each freezing zone using Satt Automation high-performance fans with frequency converters to obtain the best energy efficiency and appropriate airflow for different product kinds. Some light products don’t require more than 75–85 percent fan speed, and some only require 30 percent, resulting in significant energy savings.

Annual Maintenace & service

We perform preventative maintenance services under an AMC (Annual Maintenance Contract). We help you plan and implement the most efficient preventive maintenance programme for maximising the performance of your assets, including as drives, programmable logic controllers, motion systems, and operating systems, with Preventive Maintenance Services.