Turnkey Automation Projects

Turnkey Automation Solution

On a turnkey basis, we perform control and instrumentation projects, which include engineering, procurement, installation, and commissioning. Including commissioning help, a control system package with PLC, SCADA, and DCS is provided. PLCs, HMIs, VFDs, Soft Starters, and other automation devices are available, as well as detailed engineering, retrofitting/revamping, and AMS services.

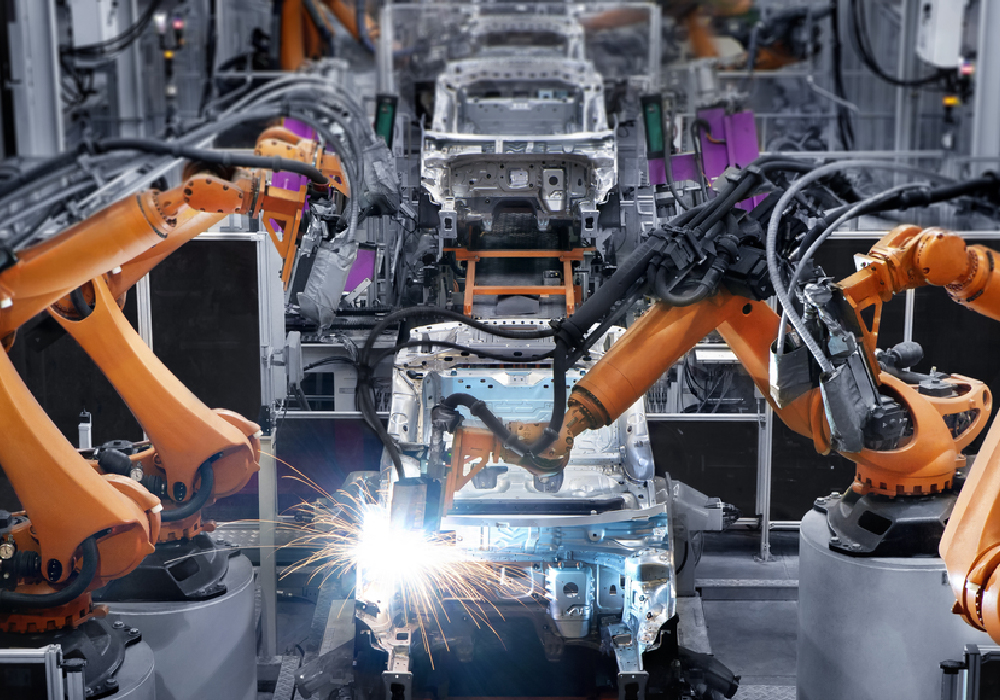

Automated assembly line

We specialise in the design and manufacture of assembly line production systems and testing lines at Satt Automation. We have extensive experience handling a wide range of components and assemblies weighing anywhere from 5 to 32 tonnes. All of our solutions and products have been designed with superior engineering technology and client satisfaction in mind. We provide solutions that meet the highest international requirements at a reasonable cost. We are proud of our long list of satisfied customers in the automotive, white goods, and farm industries.

In the areas of automotive, white goods, farm and construction equipment, and general and heavy engineering, we are proud of our excellent customer references. Our customer base in areas like food and pharmaceuticals, trains and metros, and defence is rapidly expanding.

Automated Machining Line

The automation of machining lines, also known as transfer lines, which are serial machining systems used to produce huge batches of products. They consist of a series of workstations as well as an automated handling system. Every cycle time, each workstation performs the same set of processes. Product analysis, process planning, line configuration, transport system design, and line implementation are all steps in the design of transfer lines.

With the procurement of cutting-edge machinery and lines, our team has enabled us to extract the full potential from highly automated departments.

We employ a robot-controlled facility that can autonomously bend even large-sized stainless steel sheets for huge series production.

Specialized operators perform higher-precision finishing and control activities.

Automated material handling and logistics

Material handling refers to how materials and goods are moved, protected, stored, and controlled throughout the manufacturing, warehousing, distribution, consumption, and disposal processes. Material handling is a process that includes a variety of manual, semi-automated, and automated equipment and systems that assist logistics and keep the supply chain running smoothly.

In production, distribution, and transportation, a company’s material handling system and practises are put in place to improve customer service, reduce inventory, shorten delivery times, and minimise total handling costs.

Materials and products are moved, protected, stored, and controlled using a variety of manual, semi-automated, and automated material handling equipment and technologies during manufacturing, distribution, consumption, and disposal.

Automated control system

Automation Control System (ACS) is a control theory application utilised in various control systems for operating equipment such as machinery and processes in factories to regulate activities without direct human intervention. With initiating, stopping, monitoring, adjusting, and other functions, an ACS maintains and improves the functionality of a controlled object.

Automation control systems are becoming increasingly important in a variety of industries. They are frequently regarded as technical solutions, although they are the responsibility of the senior engineering team at the coalface.

Secure infrastructures for communications and data transfers, as well as smart devices for data collecting, are required for automation control system solutions. Sensors on machinery and equipment are typically used to accomplish this.

Annual maintanenceand service

For each product, we provide AMC (Annual Maintenance Contract) for Fire Fighting Systems. We offer a full-fledged team that will manage all of your Fire Detection and Protection Systems for you. We can keep the systems running smoothly and without errors with our maintenance service.

Even the best firefighting equipment may fail to function when needed if it is not serviced and maintained.A service and maintenance contract lowers the chances of equipment failure when it’s needed, protecting your assets and your business.

Periodic PMS (Preventive Maintenance Services) are included in the services, ensuring the safe operation of all installed systems. Spare parts and consumables, on the other hand, are charged at market rates.